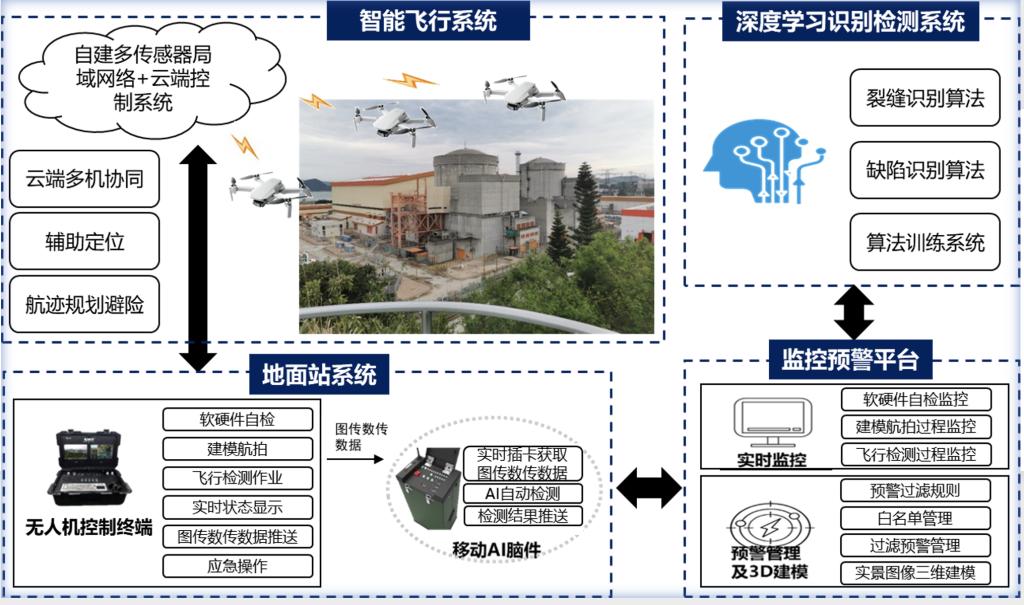

The industrial big data intelligent analysis project has developed the world'sfirstintelligent robot for detecting surface defects in nuclear power plant reactor containment, effectively ensuring the safety of important facilities in our country. The crack width recognition error is0.05mm, the defect positioning error is less than10cm, and the defect detection rate isgreater than 90%.

The key technologies include:

1.The SLAM algorithm of point-line feature fusionextracts corner points from continuous frames, tracks the corner points using the KLT optical flow method, and extracts line features using the LSD line segment detector.

2. A multi-branch detection model based on therotating frame crack detectionperspective, and a loss function based ongeometric distance perceptionis used to extract differential deep features.

The technology as a whole has reachedthe international advanced level, and the algorithm for identifying tiny cracks and defects has reached the international leading level.